Having a spare hour last night, I fancied a quick stab at getting the wiper motor out. Some rumours suggested it weighs up to 7kg, but I wasn't too sure - so there was only one way to find out.

Here's my removal guide on a metric Duratec car - your car may differ, so I'd suggest reading the whole post before attempting it yourself (however it was pretty straight forward).

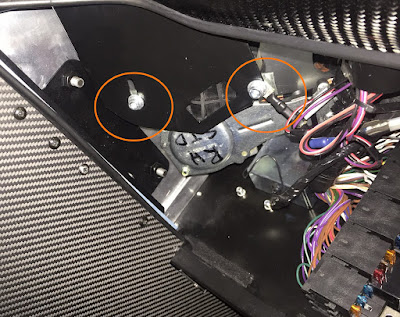

Firstly remove the what I call 'Knee Panels' - and you'll get access to these two bolts under the dash in the passengers footwell (circled in image below). These two bolts hold the rubber u-clamp in place, which subsequently keeps the wiper motor tightly fitted. It's a little fiddly to remove these due to access, but there is a nyloc nut on the upper side which you can't see, so use a 10mm spanner to secure these whilst you undo the allen bolts.

|

| Two allen bolts hold the u-clamp and subsequently wiper motor in place |

With the wiper motors' u-clamp removed, the wiper motor should be just resting on the metal panel (pictured above). You then need to remove the two nuts around the wiper motor spindles, as these are holding the spindles into the scuttle.

|

| Removing these nuts loosens the wiper spindles from the scuttle. |

With the wiper spindles loosened, remove the black plastic parts and then the spindles should just push down through the scuttle. Now the next part is a touch fiddly....

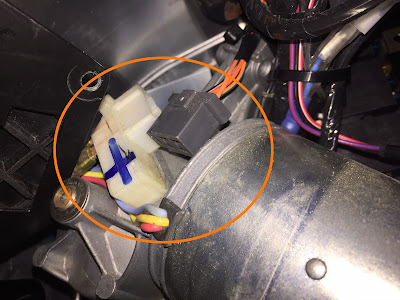

You need to move the wiper motor around so that it is free from the 'holder' but whilst you do that you need to ensure that you remove any tie-wraps that could be keeping any wiring tight (or restricting access) and then remove the connection block for the wiper motor, pictured below.

|

| Make sure you unclip the connection block |

Once you've jiggled the motor round, (and unclipped the connection block!) it should be 'hanging loose' a bit like the image below.

|

| Caterham wiper motor 'hanging loose' |

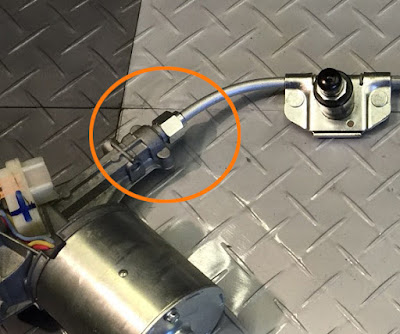

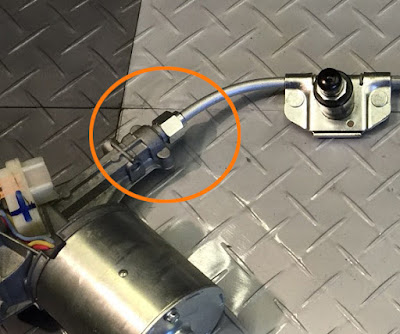

With the wiper motor 'hanging loose' I tried to jostle the lot out, but quickly figured out it's far easier to take the lot apart and then remove it bit by bit. Firstly undo the nut I've highlighted in the image below, which basically holds the mechanism together.

|

| This nut holds the main mechanism and tube together |

With the nut (above) loosened, you'll be able to pull the twisted wire through the tubes and the motor will be free. All you'll be left with is the tubes and the wiper spindles which are clamped together, simply loosen these nuts with an 8mm spanner and the tubes come free.

|

| Use an 8mm spanner to loosen these nuts to remove the spindles from the wiper tube |

With the spindles removed from the wiper tube on both sides, all that's left to do is free them from the tangle of wires (ensure you remove any tie-wraps that may cause a snag) and that's the job done. (note the passenger side is easier than the drivers side due to the tube length).

The image below shows the top of the scuttle with the wiper motor removed and spindles removed but now there are two holes (well three once the washer jet is removed). I guess an easy way to fill these holes would be to use a couple of rubber grommets, but I personally don't think it'll look that nice/clean, so a new scuttle has been ordered (and delivered a few weeks ago) so I'll be getting that painted and will be fitting the new scuttle in the not too distant future.

|

| Scuttle showing wiper motor removed and two (well three!) holes - easily fillable using some rubber grommets |

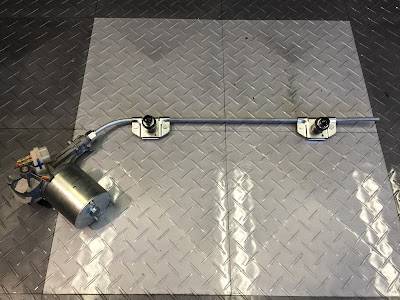

And here's the offending article! The wiper motor and spindles.

|

| Caterham wiper motor and spindles |

Now time for the inevitable weigh-in... Not quite the rumoured 7kg, but 2.43kg so a decent saving.

|

| Caterham Wiper motor and spindles weighed in at 2.43kg |

Considering the relative ease of removal, and the weight saving I think this was a decent 'downgrade'! And definitely some more lightness added, so I'm happy. Total time was around an hour and a half.

Hopefully this afternoon I'll get the seats back in, fire it up for the first time this year and go for a quick blat... I also discovered there's a weighbridge quite local to me, so may take the car over there to see what the current 'new' weight is too.